For AGVs and AMRs that require high-frequency, high-availability operation in warehousing, logistics, and manufacturing workshops, wireless charging technology offers highly automated, highly reliable, low-maintenance, and efficient charging capabilities, significantly enhancing the overall performance and cost-effectiveness of material handling systems. It not only overcomes many limitations of traditional charging methods but also serves as a key infrastructure for flexible production and smart logistics. With large-scale adoption and technological iteration, wireless charging has become the ideal energy supplement solution for modern AGV/AMR systems.

无需精确对准充电插口,AGV仅需停靠在发射线圈大致区域即可建立充电连接,提高系统鲁棒性和成功率。

无需人工介入,AGV/AMR可自主定位至充电区域实现自动能量补给,支持真正意义上的24/7不间断运行。

支持碎片化充电,在任务间歇、装卸货等待等空闲时段即可进行短时补电,实现“即停即充”,大幅提升设备可用性和任务连续性。

传统接触式充电桩需频繁插拔,易导致插头烧蚀、变形和接触不良,无线充电则完全避免机械摩擦与电火花。

发射与接收端可采用全密封结构,无惧粉尘、油污、潮湿等工业环境常见干扰,尤其适合食品、医药、化工等行业。

从根本上避免人员误触、电弧放电或短路风险,符合CE、UL等国际安全标准。

充电区域无外露电线,杜绝AGV运动过程中扯线、缠线风险,保障人车混场中的安全。

无物理接触设计极大降低故障率,避免因插座损坏、线缆老化等带来的停机维修。

无需专人插拔充电,也省去了为充电桩专门布设强电线路与保护装置的成本。

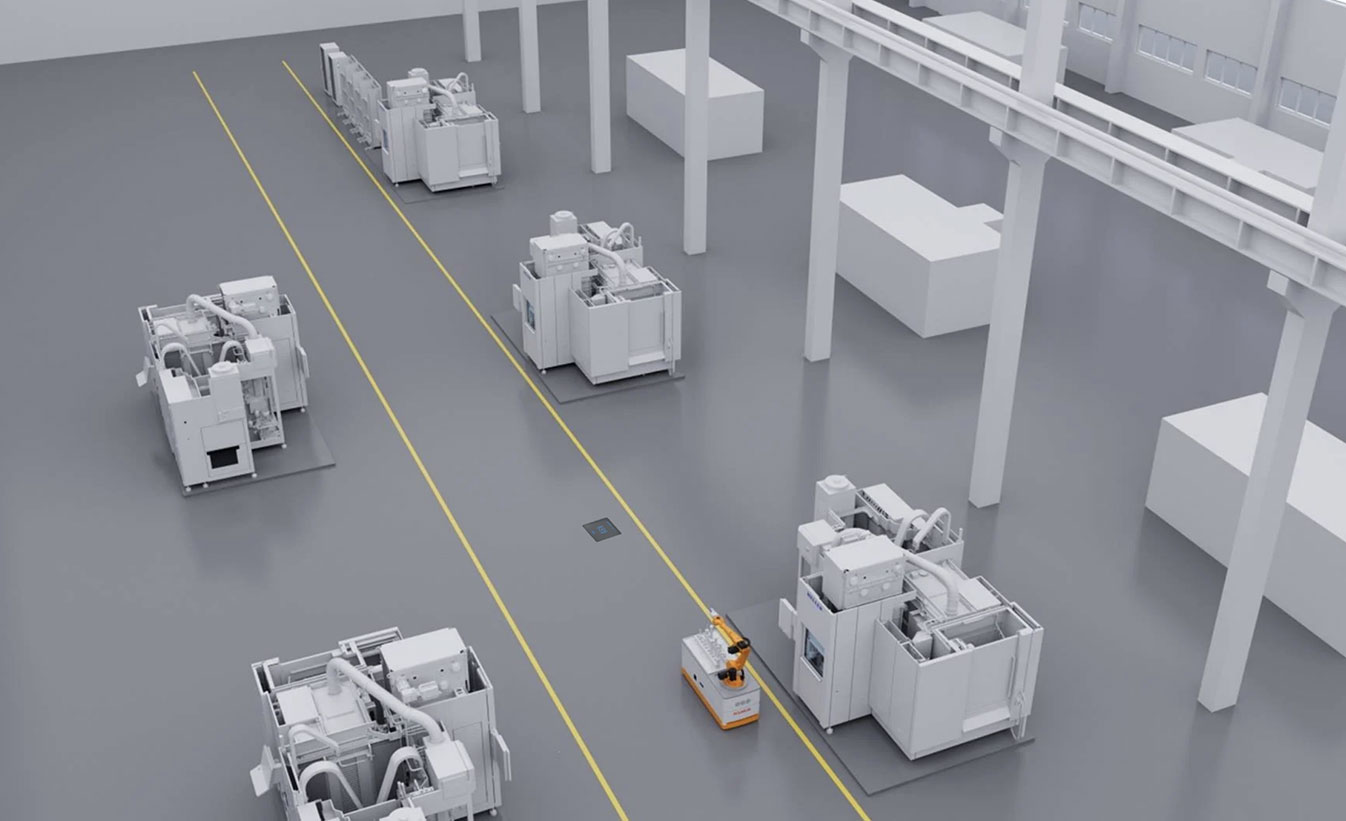

充电点灵活部署,可根据作业节拍和物流路径在关键节点快速增设充电位,无需土建改造,随线体调整而移动。

与调度系统无缝集成,支持实时能源管理与策略优化,系统可依据电量状态、任务队列智能决策充电时机,实现能效最优化。